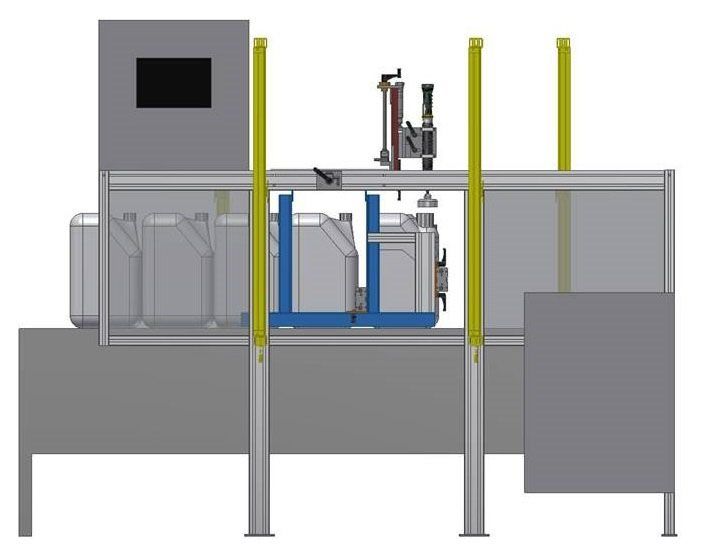

Semi-Auto Pnumatic Capper

In 2019 MAP Electrics completed a project for NuFarm Australia Limited which involved creating an automatic bottle capping machine. MAP was responsible for the electrical work and control of the system, whilst Celltech Australia designed the frame and mechanical structure for the system.

MAPS part of the system involved PLC programming, HMI design and programming, Installing light curtains and E/Stops for safety and all the electrical work to control the pneumatics.

The system involved filled bottles traveling along the conveyor and enter the capping area, causing an the entry gate to close to stop the next bottle from entering, an exit gate would also hold the bottle in place for the capping process. The MAP designed system would then send a signal to the capping head to tighten the cap, the system would then verify if the capping process was successful or not, if so it would open the exit gate allowing the bottle to continue down the line and then allow another uncapped bottle to enter.